Bronto Skylift for Industrial Firefighting

Saving people and property with aerial platforms

Mobile versatility for a wide range of operations

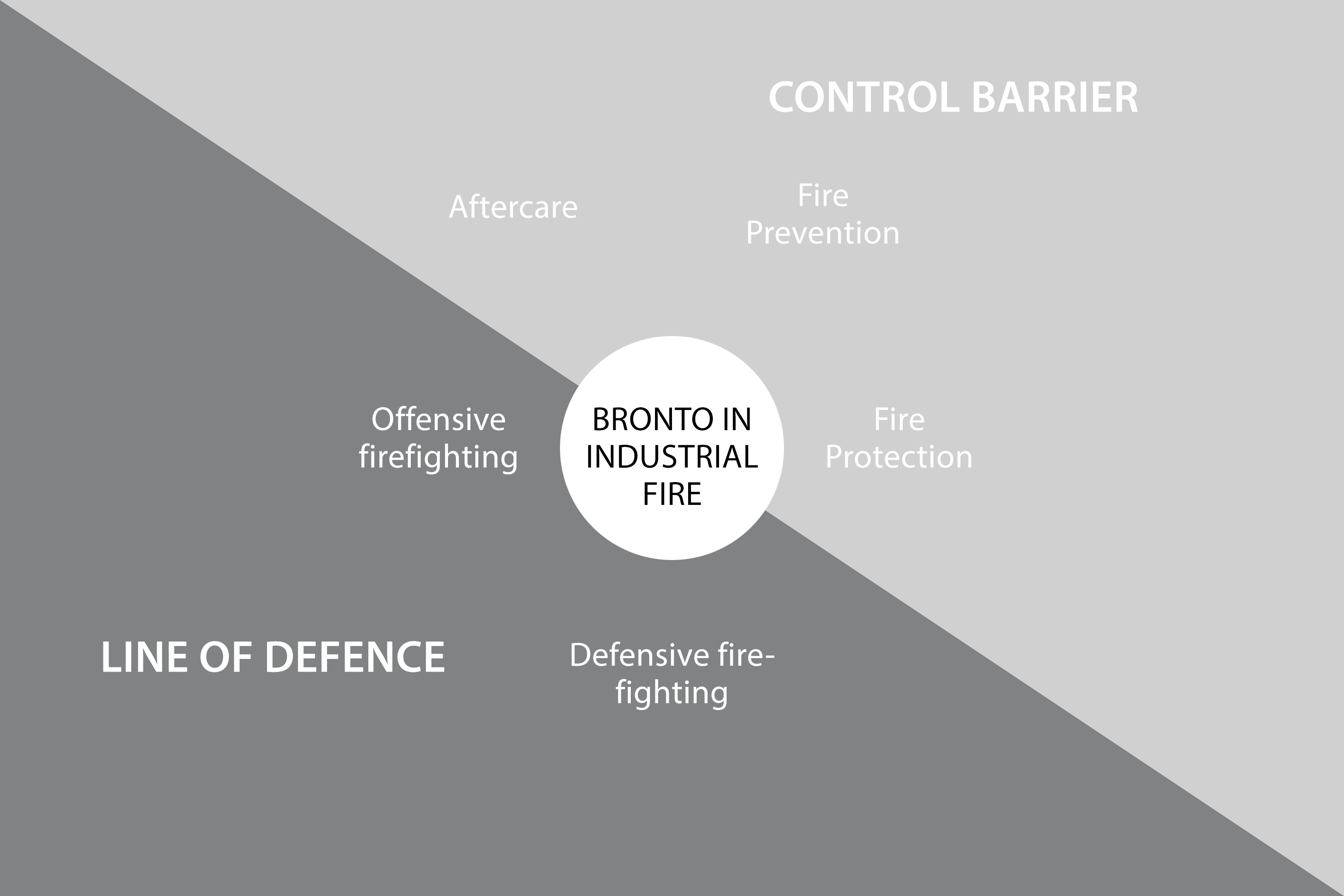

Industrial firefighting sets special demands for equipment. The presence of hazardous materials and the intensity of fires requires fast response and high water discharge capacity. With 50 years of experience, we keep you equipped with safe and effective fire appliances. They are built to overcome challenging situations and to help you safeguard people and critical infrastructure.

Bronto Skylift provides different solutions to industrial firefighting in oil and petrochemical plants and each unit can be tailor-made to match customer specifications and requirements. The product line has two aerial ranges specifically designed for industrial use, the F-WFT and F-SE ranges. Both ranges offer unique solutions to equip fire departments with the right tools to prevent and extinguish fires in complex industrial facilities.

.jpg)

Why aerial platforms?

Versatility. Aerials can be moved around factory areas and used in different areas: inspection, surveillance, shielding, cooling, extinguishing different types of fires, rescue missions, diluting toxic spread etc. Aerial platforms provide flexible application of all existing foam types and can be strategically positioned in hilly and tight areas.

Reach. Bronto WFT and SE series aerial platforms provide maximum horizontal and vertical throw distances, can reach over and beyond obstacles and have an integrated large capacity water/foam and dry powder lines that deliver straight to the target in difficult locations

Health and safety. Aerial platforms allow you to save injured people from high or difficult to reach structures. The units can also be remotely controlled for a distance or even memory driven to a certain specified spot to secure user safety. In addition, aerials support firefighters by providing a feeding line, water protection and evacuation.Where can aerials help?

Tasks best served by aerials

- Fire prevention, protection & suppression

- Saving people and properties

- Situational awareness & support

- Line of defense "when all else fails": Powder/foam/water effectively to difficult-to-reach places

Areas best served by aerials

- High structures, like cracking plants and distillation towers or structures requiring horizontal outreach

- Complex structures

- Structures having no permanent fire protection systems or where they are not working properly

- Process areas with complex pipe structures

- Tank areas

- Ports

"One of the most important factors that made us buy a Bronto for our refinery is the ability to provide foam/water streams at high level."

"If a high level fire was identified in the refining units, the Bronto can be used to provide water spray curtain/streams to ensure efficient cooling or extinguishment."

"Three most important factors are to secure access to towers in process, to reach above tank roofs in the hilly site our refinery is built on and the throwing length for foam/water."

Ensuring industrial fire safety at Neste oil refinery

The Kilpilahti industrial area is the home to the biggest oil and chemical industry hub in the Nordic countries. This impressive 13 square kilometre area houses nine different companies that form a unified production chain from crude oil to plastics and directly employ over 3500 people.

The Neste refinery in Kilpilahti includes four production lines and over 40 process units, as well as a wide tank area and the biggest harbour in Finland in terms of volume. Safety precautions in this kind of complex need to be very strict and preparedness is everything. The refinery’s industrial fire brigade is constantly planning, practising and preparing for anything that could happen in the area.

The specific needs in the industrial area, quality requirements and the specifications needed from the equipment finally led Neste to Bronto Skylift after competitive bidding.

.jpg)

.jpg)